While listening to the healthy home podcast called ‘Non-Toxic Environments’, I learned that wood glues, which are advertised as ‘non-toxic,’ may be, in fact, very toxic. Particularly the ‘less-toxic’ water-based wood glues!

As I’m trying to improve the indoor air quality of my home, I asked a local carpenter to build a table so I could control the materials used in the process, and avoid toxicity polluting the indoor air of my home, off gassing from finishes commonly used on wood furniture. In addition to controlling the materials used for finishing, I realized that I needed to take a closer look at the GLUE being used to put this furniture together to achieve a truly non-toxic piece of furniture.

What would be worse than realizing the the expensive furniture you just paid for is off gassing toxic chemical fumes into your indoor air? You might as well just shop at Ikea or Bilt-Rite Furniture, and save your money!

In order to get real data, to facilitate factual, rational decisions when making such large investments, and in order to obtain buy-in from any local carpenter, I realized that I needed to make an initial investment to have the wood glues tested.

Some people think that paying this much attention to something as small as glue is ‘fear mongering’ and a waste of time, but I think it it stupid to use toxic glue, or any material, when there is a better alternative. We should take care to identify the best materials.

Preparation for the Test

I asked a Milwaukee-based furniture maker (Sustar Woodworks – highly recommend!) to create 2 sets of wood/glue samples, using the 4 main types of wood glues used today:

- Titebond Original Glue

- Titebond II Glue

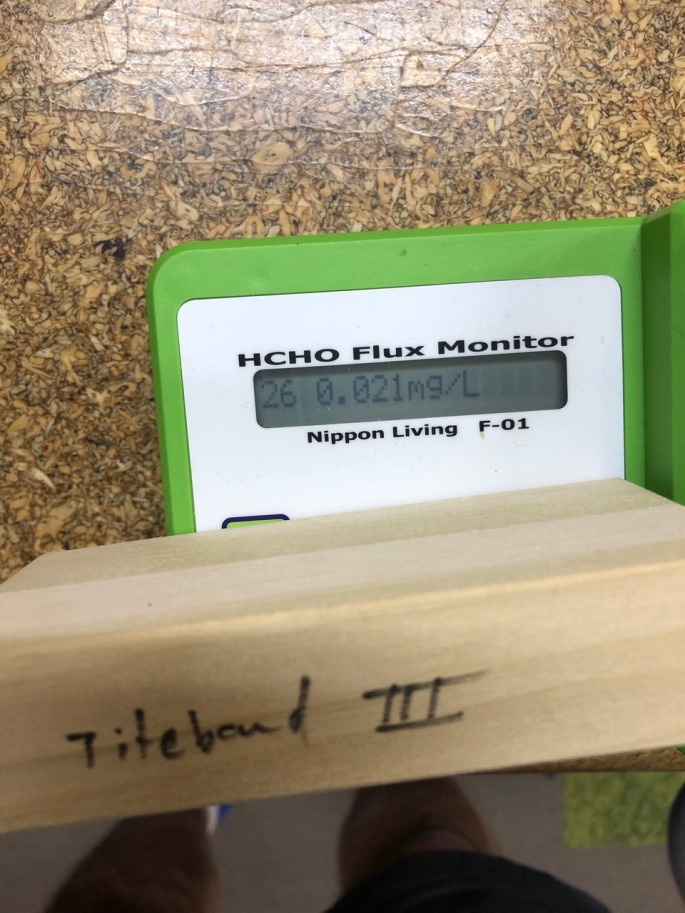

- Titebond III Glue

- Titebond Hide Glue

To be clear, this is a picture of the Titebond Hide Glue product that we tested:

The picture below shows the types of samples which were created and used for the FRAT test (Formaldehyde Release Attenuation Test).

- Glued Joint – the samples in the back consist of two pieces of wood glued together. You can see the joint in the top middle, where the glue was used to hold the two pieces together.

- Glue Exposed to the Air – the samples in the front consist of one piece of wood, with glue applied to the top side of the piece.

What Test is Used to detect toxicity and off-gassing?

The NTE-3100 Flux Monitor is a FRAT device that was developed in Japan, and utilized to some extent in the LEED building certification programs that were developed in the USA.

The NTE-3100 Flux Monitor uses the Formaldehyde Release Attenuation Test (FRAT) sensors in its system to pinpoint which exact surfaces release formaldehyde, and how much formaldehyde they release, within accuracy of 1 part per billion (ppb). This test device is portable, and can be used without disrupting the surface of the materials which are tested. The results are available in 30 minutes.

Although there are literally hundreds of thousands of chemicals that are used in the home and interior decorating/furniture materials used in our homes, it is not currently possible to test for the presence of all of them. Formaldehyde is a good place to start in measuring these chemicals, because of the nature of formaldehyde. When formaldehyde is present, we can be confident that other off gassing chemicals are also present. Thus, formaldehyde is a good indicator for overall toxicity.

Don’t let this lull you into a false sense of security though. Even if your material tests zero for formaldehyde, there is always a possibility that the material contains other chemicals. That is why it is so important that manufacturers start operating with transparency and ‘open-source’ attitudes, rather than keeping their ingredients secret due to worries about competition. SDS (safety data sheets) rarely list any ingredients at all, much less the entire list of ingredients. And as we consumers now understand, ‘zero-VOC’ has nothing to do with human or animal health, and zero-VOC products and water-based products often contain even more Hazardous Air Pollutants (HAPs).

How Does the NTE-3100 Flux Monitor (FRAT) System Work?

- Glued Joint – the samples in the back consist of two pieces of wood glued together. You can see the joint in the top middle, where the glue was used to hold the two pieces together.

- Glue Exposed to the Air – the samples in the front consist of one piece of wood, with glue applied to the top side of the piece.

How Did I Get Access to This Testing?

Andy Pace of The Green Design Center in Waukesha, Wisconsin, USA, connected with the developers of the FRAT device in Japan. The Green Design Center is now the exclusive North American importer of this device from Japan, and is on a mission to get these devices into the hands of indoor air quality experts across the country. Indoor Air Quality (AIQ) experts have used testing devices that can test the general indoor air quality for formaldehyde, but they aren’t able to pinpoint which materials are causing the problem with the devices that have been available up to this point.

“The potential this device has as an in-field tool in the hands of trained professionals is where our current focus is. We believe that this system can and will shift our industry away from doing air sampling and guessing of the source, to pinpointing the exact location and SOLVING THE PROBLEM.” – Andy Pace of The Green Design Center

I am lucky in that The Green Design Center is within an hour’s driving distance from my home!

The Green Design Center has been using this FRAT test system for about 4 years as a method to determine the effectiveness of their coatings or AFM Safecoat paints to seal chemical offgassing. It has been invaluable to show that AFM Safecoat sealers can block formaldehyde 100% in many cases. In addition, The Green Design Center has tested the off gassing of thousands of home building and home interior products!

What are Safe Levels of Chemical Gases Inside the Air of Your Home?

There are several organizations that offer guidelines or limits for levels of gaseous chemicals circulating in indoor air — specifically, formaldehyde gases. The Word Health Organization and OSHA are the most well known organizations, but OSHA is the only org whose limits are associated with any legalities — and of course, these limits are not highly enforced.

Maximum Limits for Formaldehyde in Indoor Air

- OSHA – 40 ppb, over 8 hours

- WHO – 2 ppb over the long term

- LEED Certification – 27 ppb

How does this relate to our homes?

To illustrate the toxic impact of an interior material (area rug) most people consider to be benign, let’s look at a real life situation (below). This situation also illustrates the need for real and exact testing, as the FRAT device pinpoints the exact materials causing the problem.

Situation: Hardwood flooring and area rugs were installed/placed in the home at the same time during a remodel. Almost all family members began experiencing health issues, mainly flu symptoms that did not subside. They hired an Indoor Air Quality expert (IAQ) to assess the home, and then called Andy Pace from The Green Design Center for second opinion.

“6200 square feet of refinished hardwood flooring that was assumed to be offgassing enough formaldehyde to cause severe health issues with the homeowner.”

It is often thought that the finishes and glues used in hardwood flooring causes toxic off-gassing – and sometimes, it does! But in this case, it was not the culprit.

“[The homeowner] had professional IAQ (indoor air quality) testing which showed air formaldehyde levels at the critical level (83ppb average throughout the home).

“[Andy Pace of the Green Design Center] tested 25 individual surfaces of the home and determined that the wood flooring was harmless. $45,000 worth of flooring removal and replacement saved.

…the dozen or so area rugs throughout the home were releasing formaldehyde at levels of 100-350 ppb. [The ability to pinpoint the true off gassing culprits] saved them [$45,000 worth of hardwood flooring removal] as well as months of agony and mess.”

As you can see from the example above, the FRAT test, which is done directly on the surface of the area rugs, showed a level of 100-350 ppb, depending on the rug (there were several throughout the home).

However, the ambient air level of formaldehyde was only 83 ppb. This shows how the solution to pollution is DILUTION. Meaning, that although a surface may be off gassing at a certain level (100 – 350 ppb), as the gases radiating from the surface mixes within the ambient air of the space, it becomes ‘diluted.’

However, if one adds up ALL of the items that are off-gassing in the home, the higher the level of toxic gases will be in the ambient air. And as you can see from the example above, several area rugs were enough to degrade the ambient air quality to a a critical level which caused health issues.

If the family had not remediated the situation, the flu symptoms they began experiencing could have turned into chronic disease as the body’s strength and ability to function were slowly undermined by an overload of chemical exposure.

The level of chemical gases in the home were MORE THAN DOUBLE the legal level set by OSHA, and 41.5 TIMES the limit set by the World Health Organization.

The Results of Wood Glue Testing

You can see pictures of the results as measured by the FRAT device below, as measured in the context of a .10 meter-long glue joint, as well as measured when the glue is exposed directly to the air, applied to a wood surface.

Glue Area Exposed to Air

- Titebond Original Glue – 0 ppb

- Titebond II Glue – 99 ppb

- Titebond III Glue – 50 ppb

- Titebond Hide Glue – 0 ppb

Glued Joint (Seam)

- Titebond Original Glue – 0 ppb

- Titebond II Glue – 13 ppb

- Titebond III Glue – 21 ppb

- Titebond Hide Glue – 11 ppb

The substance we wanted to test in this case was the GLUE, however, it must be tested in the context in which it is USED, which is, within the JOINT between pieces of wood, as we see in furniture. In the interest of completeness, we also tested the same glues again, when applied to area of wood surface, completely exposed to the air (not within a joint).

- Glued Joint – the samples in the back

- Glue Exposed to Air – samples in the front

Both sets of samples were made, and the glue allowed to cure for at least 7 days before testing.

The samples are all about 4.5 inches long, which is roughly 1/10 of a meter length.

Testing Results Analysis

The results show us that the water-based wood glues (Titebond II and III) have the highest levels of off-gassing formaldehyde, between 13- 21 ppb when measured in the context it would be used in a piece of furniture. Although this isn’t as high was the levels measured in the area rugs we discussed earlier in this post, it is still substantive.

Titebond Original tested at zero for both sample types.

Titebond Hide Glue tested at 11 ppb on the joint, and 0 ppb on the glue exposed to the air.

There isn’t any reason beyond convenience, that carpenters can’t use completely non-toxic, REAL hide glue (not the Titebond hide glue pictures above), that can be mixed up from dried material that is obtained from melting down animal hides. Real hide glue is very durable, except when exposed to moisture and heat. Therefore, real hide glue may not be suitable for cutting boards, for example, but could very well be used for desks, bed frames, and other furniture that is not used in the kitchen. Spilling a bit of water on a desk is not going to cause the glue to become compromised.

“Hot hide glue was the glue used by almost all woodworkers and furniture factories until the 1950s when white glue – polyvinyl acetate (PVA) – became available. Elmer’s was one of the first of these glues.” – Bob Flexner

“you can assume that almost all furniture and other wood objects made before the 1950s were glued originally with hide glue, and all repair work done before the 1950s was done with hide glue. (I believe that a major reason for the survival of so much old and antique furniture is due to hot hide glue being the only glue available for so long; I’ve seen so much destruction caused by the use of modern synthetic glues.)” – Bob Flexner

- Bjorn Hide Glue is a potential source. I’m waiting for a response regarding if their product has additives.

- Unfortunately we can’t trust Milligan & Higgins, because they have additives in their glue which they refuse to disclose. In addition to that, they were extremely aggressive when asked to declare their ingredients, so I recommend boycotting this company until they agree to disclose their ingredients and give consumers respect for wanting transparency. If a company becomes aggressive when they are asked to be transparent, that is a HUGE red flag.

- 192-gram strength should be sufficient for most furniture. Higher gram strengths may be unworkable in woodworking because the higher the gram strength, the faster is dries. Resellers include Woodworker’s Supply, Tools for Working Wood, Merit Industries/Wood Finish Supply and a number of suppliers to the musical-instrument industry.

- Make your own hide glue

- Learn how it is made here.

- Benefits of real hide glue

- It is reversible

- washes out of your clothes

- largely transparent to stains and varnishes

- doesn’t suffer from creep

- easy to clean up, today, tomorrow or 100 years from now

Yes, the Titebond Original glue tested zero in both sample types, but, as I mentioned earlier in this post, there could be other undesirable chemicals in these formulas that we are not able to detect with the FRAT test.

I would be satisfied with the use of Titebond Original if a carpenter insisted upon its use. But I would very much PREFER real, non-toxic hide glue. We then must be careful that the carpenter is not ADDING any toxic substances to his mix when he prepares the real hide glue!!!

We are so used to believing the the substances available to us are benign, that sometimes we don’t even realize what we’re doing unless we change our mindset to be super skeptical and we maintain the skepticism with diligence.

The more materials we add to the home that are off gassing or even degrading as particulates into the dust of our homes, the less healthy we are, as our bodies have to work harder to eliminate these chemicals, each day.

These chemicals are literally inhaled, ingested from hand to mouth contact, or absorbed through the skin, over and over, each and every day, again and again. It’s a depressing cycle that repeats every 24 hours – ever seen the movie ‘Groundhog Day’ with Bill Murray?

These chemicals are literally inhaled, ingested from hand to mouth contact, or absorbed through the skin, over and over, each and every day, again and again. It’s a depressing cycle that repeats every 24 hours – ever seen the movie ‘Groundhog Day’ with Bill Murray?

Our bodies ‘detoxify’ and expell these chemicals again, on repeat, each day, through our sweat, our urine and our feces. But this process of expelling requires energy and effort. Wouldn’t it be wonderful if we all had more energy? We could put that saved energy TOWARD more productive endeavors, like playing with our kids, growing our businesses, growing a garden, and just thriving more in general without the burdens of health issues and diseases. Everyone is different, and some are positioned to have more strength, better detoxification function, and better epigenetic expression of their genes than others. That is why some members of the home may be suffering more obviously than others when it comes to thriving or not thriving when under chemical exposure stress.

The cycle: exposure > ingestion/inhalation > detox cycle > exposure > ingest…. will continue to repeat until we learn how to change it, by removing these chemicals from our homes.

We have a lot of chronic fatigue, learning disabilities, lowering of IQ, and chronic diseases and organ failures going on right now in our children, young adults, and middle-aged citizens. The life expectancy pundits show that the current generation will live shorter lives than their parents. How could this be?

Our grandparents and parents were exposed to some of the chemicals we now consider to be ‘the worst’, like DDT, lead, asbestos, mercury, and others. If they were exposed to such hazardous substances, how can they be living longer than us today?

Perhaps it is because although we’ve banned DDT, it is still pervasive in the environment. Lead is EXTREMELY pervasive in our environment, as we drink our tap water out of lead pipes, etc.

Other substances, such as asbestos are actually STILL LEGAL in the USA, and are used in some industries and materials!

Although our hat-makers no longer use mercury to make top-hats, our grandparents and parents received and still have amalgam cavity-fillings which are roughly comprised of 50% straight up mercury. Actually, although many of our grandparents, such as my grandfather who died in his 90s two years ago, lost many teeth, or ended up with dentures, many of them didn’t have as many fillings as our baby boomer parents or grandparents have today.

Dentists have begun moving away from using amalgam fillings, instead turning toward plastic composite fillings, but the plastic composites contain BisGMA, UDMA, TEGDMA, HEMA and other substances that can potentially off gas and become ingested as they wear down and or shrink while in the tooth. We don’t often know the toxicity of the new materials or technologies we embrace, until decades and decades have passed, allowing time for extensive scientific study and measurement. Conventional dentists are often slow to adopt new technologies, as we’ve seen in the case of mercury fillings, and we see again in regards to the potentially safer Admira Fusion ceramic composite that is now available.

So, although we’re no longer ACTIVELY spraying DDT in this country, it remains in our environment. We ARE still ingesting lead in our water to a great degree, although we may not be ingesting or absorbing it as much as we’ve abandoned the use of leaded gas, etc. We are still exposed to asbestos which remains on many buildings, and asbestos is still used in various industries and products. Mercury fillings have been replaced with other toxic substances, and we are still exposed to mercury in ways that our grandparents weren’t, through the fumes coming out of our recycling plants, and from our CFL light bulbs, for example, that do off-gas when they are on/heated.

Not only are we still being exposed to the substances we think of as no longer present, but we are also born from mothers who were exposed to these substances, and also who had mercury fillings while they were pregnant. Pregnant mothers actually pass on toxic substances they carry in their bones and tissues and teeth, along with nutrition and oxygen, through the placenta, to their fetuses.

This process is called ‘bio-accumulation’, which describes the process of organisms accumulating the previous load of a other organism, and then accumulating their OWN load of toxic substances. The term ‘bio-accumulation’ is often used in discussions about fish, as we are told to avoid eating tuna and other large fish who ‘bio-accumulate’ toxins as they eat many other organisms. Bio-accumulation can occur in either scenario – through fetal absorption, or through the consumption of other organisms, or both, as fish procreate as well as eat other organisms, as do we humans procreate, as well as consume other organisms, such as fish, meat, plants, etc.

In addition to these continued exposures, we have a GREAT MANY ADDITIONAL chemical to which we are exposed. We like to think that our world has gotten safer, but unfortunately the chemical use has continued to increase and the number of chemicals used has also increased. Glyphosate, the active ingredient in many herbicides like RoundUp and Ranger Pro, is a dangerous clastogenic substance that causes cancer, miscarriage, and DNA damage, yet it is one of the most, if not The most, pervasive chemical in our environment (water, air, soil), today. I believe we will one day view glyphosate as even more deadly than DDT. I could give example after example of the chemical exposures burdening our bodies today.

The US government approves new chemicals which manufacturers present. However, there is a backlog, and if the approving agency cannot get to an application within the specific period of time (which may be 90 day or so?), the CHEMICAL IS AUTOMATICALLY APPROVED, in some cases, as I currently understand.

Oil-based paints, which are now devoid of lead, have been reformulated due to the VOC-regulations imposed by the USA EPA in the 1990s, and now contain thousands of NEW chemicals that are actually Hazardous Air Pollutants. It can be argued that the new paints, including zero-VOC, are MORE toxic for human occupants, than the old oil-based paints were!

We’ve all been led to believe that zero-VOCs mean increased indoor air quality and human health. But this is FALSE.

The regulations requiring that paint be free of VOCs has nothing to do with human health or toxins, and has everything to do with outdoor air pollution.

Almost all zero VOC paints emit formaldehyde and a list of other chemicals that harm us. Specifically, zero-VOC paints contain Hazardous Air Pollutants (HAPs), such as formaldehyde precursors that create formaldehyde during the curing process, as well as ammonia, butyl acetate, and acetone.

The EPA began regulating VOCs in various products in the beginning in the 90s, because of the propensity for them to react with low level nitrogen and UV to create smog (outdoor air pollution).

So, now we have zero VOC products, but although the manufacturers give the illusion that this means the paint ingredients are safe for human occupants, in reality, it just means that the product doesn’t contain chemicals that contribute to OUTDOOR air pollution.

And this brings us back to wood glues.

Why Does Titebond Tell us that their Products are Safe, When They’re Not?

Carpenters use the wood glues that have been provided by the wood glue industry, and they believe these wood glues to be safe. Why do they believe this? Because Titebond is telling them that the products are indeed safe. Look at the following certificate offered through the Titebond website. They are testing for VOC’s!! The term ‘VOC’ is in the NAME of the certificate! But as you now know, this means nothing in terms of the health of the HUMAN OCCUPANTS of the indoor space. They do also include formaldehyde testing, but I had to draw attention to the meaninglessness of the NAME of the certificate, to start.

CA Sec 01350 VOC Chamber Test Emissions Compliance Certificate

The formaldehyde testing is done most likely in a chamber (volume of air in cubed meter) where they are testing the ambient air, whereas in the FRAT testing we did, we tested the air coming directly off of the surface of the glued joint. They give their results in μg/m3, which stands for micrograms per cubed meter. I’m really not sure what this actually means. Does this mean that micrograms of formaldehyde per cubed meter is the unit in which their testing device is measuring?

Because of all of this, it is difficult to directly compare Titebond’s third party test results with ours. In their certificate, they say that the test sample used was 168g/square meter of surface, as you can see in “Product Coverage.” I’m not sure how many grams or glue was used for each sample even – I’d have to ask the carpenter to do a estimate and weigh it! And does the weight change if it is fresh or dried glue?

Yes, science can get really tough for consumers to do. But, we have to at least start doing SOMETHING, and that is why I so appreciate the FRAT testing that Andy Pace of The Green Design Center is doing. Although we may not be able to directly and easily compare his testing results with the results shown on this Titebond certificate, we CAN compare the FRAT test results with the results we get from thousands of other surfaces which The Green Design Center has tested.

And by comparing FRAT test results with indoor air quality results, we can at least get SOME idea of how the gasses coming off of the surfaces affect indoor air quality, when diluted in the entire volume of air within the home (area rugs off gassing 100 – 350 ppb vs. the 83 ppb ambient level of formaldehyde measured in the example discussed earlier in this post).

Oppositely, companies like Titebond offer their third-party testing certificates, like the one above, available for consumers to review, but we as consumers AREN’T able to RELATE the data to anything practical or meaningful.

Plus, the things manufacturers most often test for, are VOCs, which are completely meaningless for human health, and having no bearing on Hazardous Air Pollutants (HAPs).

Conclusion

I don’t know what our grandparents and great-grandparents used for cutting boards in the kitchen, but it is likely that real hide glue wouldn’t hold up in this application, due to the repeated water exposure on the seam of the wood in the cutting board as the cutting boards are washed. On the other hand, I wouldn’t dismiss the idea of using real hide glue in cutting boards, until someone tests it out and proves that the cutting board will fall apart.

But for the other wood items in the home, there is no reason why we can’t go back to using real hide glue, mixed up as needed by our carpenters. This may prolong and complicate the processes for the people who ARE still making real wood furniture in assembly-line type environments, and of course will also somewhat lengthen the process for local carpenters and furniture-makers as well, but perhaps this is what we need. It may increase cost, but maybe this is something we need to either figure out a way to subsidize for the masses, or save up for, as more labor for carpenter will likely lead to increase costs for furniture.

Perhaps it would lead to more quality furniture being built, with less toxic finishes, making the furniture we do create last longer, and make it easier for us to refinish and make them look new again as they are passed on from one owner or generation to another. It is difficult to take paint and stains and chemical finishes off of wood, but it is very easy to apply MORE non-toxic animal fats/beeswax mixtures, or MORE raw sun-bleached linseed oil. If a piece of furniture were to come apart at a seam, due to the failure of real hide glue, it would be very easy to provide moisture and steam to whatever other joints are needed to take the piece apart and re-glue it all back together in a solid manner.

I hope all of this information can help us become more aware of the misleading information out there, and help us get a handle on the things we need to change in our homes as we live in a very polluted world. To stop polluting, we need real data to motivate us.

Sincerely,

Your Fellow Holobiont

Glue Exposed to Air

What do you use for a chopping block? I’m trying to find an alternative to plastic ones. Thank you

LikeLike

I describe that in my post on Safe Kitchenware – I had a carpenter make me an end-grain cutting board – he did have to use waterproof glue. but i don’t know how to get around it for cutting boards.

LikeLike

Urthware makes glue-free cutting boards.

“What is our mission at urthware? To make naturally safe cutting boards and kitchenware without the toxic, synthetic and/or petroleum based chemicals found in most cutting boards. From our 100% Canadian locally sourced (100 mile) ethically harvested lumber, to our organic beeswax finishes, to our all natural gum tree rubber feet (natural latex). “

LikeLike

Thanks Hunter. I’ve looked at Urthware’s products and they look nice, although I haven’t had the opportunity to personally try them.

LikeLike

I am looking for a safe, natural or non-toxic glue to build a wood sauna. It needs to be heat and water resistant. Kinda of a challenge if you have any suggestions.

LikeLike

Hello Keith, would you be willing to call AFM, ask them if they have anything suitable, and report back here? This issue is really important and so often missed. AFM: Administration: (619) 239-0321, Technical Assistance: Jay Watts (619) 239-0321 – X 102. Otherwise, as you can see in this post, Titebond Original Glue had the lowest values when tested with the FRAT device.

LikeLike

Did you test the wood prior to the glue the confirm it wasn’t coming off the wood?

Did you test the glue on a known inert and sterile surface?

Did you repeat the experiment to verify results?

LikeLike

No, can you do these steps for us and report back? 🙂 That would be a wonderful way to advance our collective knowledge even further. I’m glad my experiment inspires you to further investigation! Curiosity is what inspires true discovery 🙂

LikeLike

Robin, stumbled across your post looking for information on toxicity of titebond wood glue. Thanks for providing the test result information. Did you ever hear back from Bjorn Hide Glue? I’m a hobbyist carpenter and I’m interested in trying out their product but would love to know if you have anymore info.

LikeLike

Thanks Eric, no, I did not hear back, unfortunately. Will you write to them and ask?

LikeLike